-

研究用材料制备

我们通过多种宿主及弹性的培养体积,生产抗体、Fc融合蛋白和其它重组蛋白用于支持各种研究与开发。可在6-12周内交付1g以上的高纯度、低内毒素水平蛋白,用于体外、体内试验和可开发性研究。

瞬时转染载体构建

瞬时转染载体构建 高通量的瞬时表达筛选

高通量的瞬时表达筛选 大体积瞬时表达与纯化

大体积瞬时表达与纯化 稳转细胞池表达与纯化

稳转细胞池表达与纯化表达系统 HEK293、HEK293F、CHO-S、CHO-K1 转染方式 PEI、脂质体、电转染 培养体积 125ml摇瓶~15L生物反应器 纯化系统 亲和层析、离子交换、疏水作用色谱和分子筛色谱 检测手段 SDS-PAGE、HPLC-SEC、IEC、WB、Fortebio、紫外分光光度法、生化和内毒素分析

-

测试用细胞构建

我们可构建一系列不同品种来源的标准亲本细胞系用于检测开发或评估候选药物。可选用带有不同标签基因的表达载体便于表达鉴定,也可参照生产用稳定细胞株流程,作单克隆化及进一步优化,从而可以实现目标蛋白成功且稳定的表达和维持。配合我们的高密度QuaCell®系列培养基和相应的检测试剂,即可成为一个快速高效的药物筛选及体外药效评价工具。

宿主细胞 HEK293、HEK293T、CHO-K1 or 客户指定细胞 质粒载体 pKS001、pcDNA3.3、pLEX or 客户指定质粒 标签 V5、c-myc、Flag、His 转染方式 PEI、脂质体、电转染

-

细胞株悬浮驯化

基于对培养基成分的深刻理解,我们建立了一整套可溯源的细胞悬浮驯化技术平台,可根据客户要求在短时间内将多种生产常用的贴壁培养细胞向指定培养体系进行驯化适应,以放大生产规模,并应用于抗体药物表达、疫苗生产及病毒包装等多个领域。

无血清悬浮驯化

无血清悬浮驯化 低血清悬浮驯化

低血清悬浮驯化 悬浮培养基切换

悬浮培养基切换

-

稳定细胞株构建

康晟生物汇聚了细胞生物学,生物分析,分子生物学等多方面的专业人士,整合了多种技术平台,可以根据客户需要的目标序列,快速构建细胞株,提供稳定、高产、合规的细胞系开发全程服务。

案例分析 基因合成及载体构建

基因合成及载体构建 瞬时或稳定表达评估

瞬时或稳定表达评估 稳定表达细胞株构建

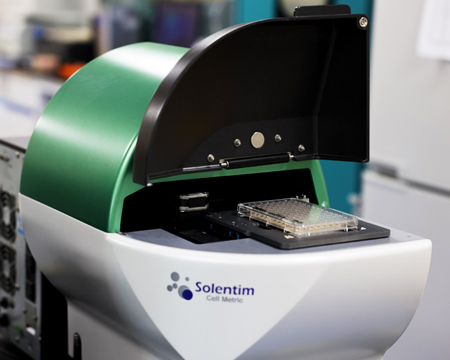

稳定表达细胞株构建 单克隆质量和产量筛选

单克隆质量和产量筛选 细胞系传代稳定性评估

细胞系传代稳定性评估 原始记录整理及申报资料撰写

原始记录整理及申报资料撰写

-

培养基配方开发

康晟生物技术团队拥有超过15年的培养基配方开发经验,可针对客户特性需求,提供多种细胞的配方开发服务。利用高通量筛选专利技术,可在最短时间内开发出最合适的培养基配方,且充分考虑后期干分化及使用便捷性,确保大规模生产交付的可行性。

CHO基础培养基开发

CHO基础培养基开发 CHO补料培养基开发

CHO补料培养基开发 其他细胞悬浮培养基开发

其他细胞悬浮培养基开发

-

产物质量表征分析

康晟生物提供一系列针对单抗及蛋白药物质量的检测与分析项目,既可作为培养基开发优化的辅助项目,也可作为单独服务项目运作。

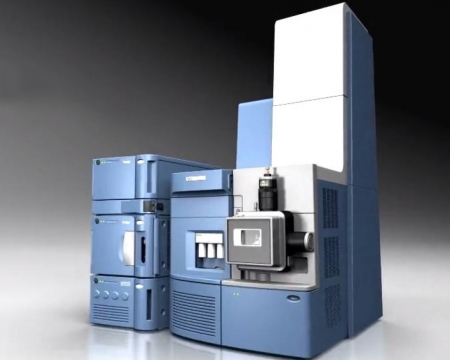

蛋白定量 紫外分光光度法、HPLC(Protein A)、Fortebio 活性检测 细胞检测、ELISA、Fc功能分析 物化性质 聚合体(SEC)、碎片(CE-SDS)、电荷异构体(IEX) 分子表征 完整分子量(LC-MS)、肽图(HPLC)、糖型(UPLC)

-

表达产物产量提高

针对已有初步工艺项目,QuaCell 可提供以提高产量为目的优化服务,通过更换/调配培养基及/或补料组合、添加/减少培养基组分、调整培养工艺等方法,发掘细胞株潜能,提升目标蛋白的表达量。

案例分析 基础培养基优化

基础培养基优化 补料及添加物优化

补料及添加物优化 补料策略及工艺优化

补料策略及工艺优化

-

表达产物质量优化

通过将培养数据与 QuaCell 项目大数据检索比对,寻找潜在的关键影响因素,并通过 DOE PB 或 RS 设计进行考量及验证,调整目标质量参数,优化表达量。

多聚体调控

多聚体调控 电荷异构体调控

电荷异构体调控 糖基化优化(G0F或其他糖型)

糖基化优化(G0F或其他糖型) 唾液酸含量优化

唾液酸含量优化 ADCC/CDC活性优化

ADCC/CDC活性优化

-

中试放大QbD研究

我们的项目团队拥有丰富的 1000L+ 反应器培养经验及多年培养基与补料开发经验,能从源头出发,帮助客户建立合格的缩小模型,提供特定细胞系的培养培育、补料策略制定、稳定性考察以及提高细胞培养物的产量等服务。

放大过程培养工艺优化及验证

放大过程培养工艺优化及验证 生产工艺关键原料设计空间认定

生产工艺关键原料设计空间认定 生产工艺关键参数设计空间认定

生产工艺关键参数设计空间认定 关键质量属性风险评估

关键质量属性风险评估 缩小模型合格化

缩小模型合格化 其他需优化项目放大过程

其他需优化项目放大过程

-

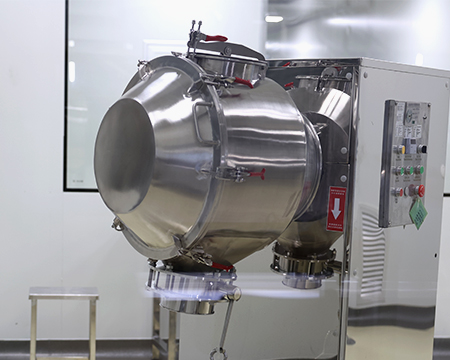

干粉培养基定制生产(GMP/ non-GMP)

康晟生物为客户提供培养基筛选和制造服务,平台配套设施齐全,备有 30L 反应器,能满足多条件并行实验设计,多参数并行测试条件,可满足放大工艺小试,已完成 30 余个优化项目。

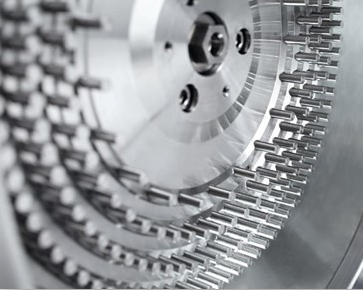

单批产能 2kg-300kg 生产设备 进口针磨设备

封闭氮气保护系统

关键因素在线控制辅助能力 免费配方评估服务

完善的原料选择方案

稳定的参数控制体系

成熟 Scale Down 模型质量保证 组分完整性保证

产品均一性检测

微量元素偏差控制交付时间 中国境内:最快 10 个工作日

中国境外:4 周内

-

液体培养基定制生产(non-GMP)

康晟生物可为客户提供液体培养基的配制配套方案,参照 GMP 干粉的原材料质量管理体系,根据客户要求和细胞特性进行配方配比的精细调整。同时提供一系列的质量检测及细胞培养验证,确保满足大规模生产的工业化需求。

客户配方委托定制生产

客户配方委托定制生产  QuaCell 配方定制生产

QuaCell 配方定制生产

案例分析 标准配方特殊定制生产

标准配方特殊定制生产

-

干粉化生产放大验证

康晟生物可提供干粉培养基和液体培养基的干粉化生产评估及设计,通过将方案放入 2kg 的 Scale Down Model 中进行测试,能最小化地降低生产成本。同时,全程提供工艺转移方案,确保干粉生产规模及发酵培养放大的顺利完成。

液体配方干粉化设计

液体配方干粉化设计 干粉液体一致性评估

干粉液体一致性评估 干粉配方稳定性评估

干粉配方稳定性评估 干粉生产稳定性评估

干粉生产稳定性评估 卫星罐同步交付验证

卫星罐同步交付验证

-

GMP无缝连接供应方案

结合制药企业的具体要求,康晟生物可以提供各种个性化的 GMP 供应及包装方案,提高使用时的便捷性、稳定性及安全性。

个性化物料编码

个性化物料编码 个性化包装定制服务

个性化包装定制服务 培养基水化模块工厂支持

培养基水化模块工厂支持 DMF调阅

DMF调阅

-

临床原料药制备

康晟生物拥有 5400㎡ 符合 GMP 级别的生产车间,2000L 和 2*200L 反应器,可以支持临床前试验样品,临床 I 期和临床 II 期试验用药品生产,已交付 20 余个中试项目。

项目成功率高

项目成功率高 项目转移效率高

项目转移效率高 转移后工艺优化能力强

转移后工艺优化能力强